In an environment where dirt, rain, and temperatures fluctuate daily, adhesive tape is the ‘glue’ that most often secures a building’s key weather resistive barriers in place.

In an environment where dirt, rain, and temperatures fluctuate daily, adhesive tape is the ‘glue’ that most often secures a building’s key weather resistive barriers in place.

Understanding Adhesive Tape and Field Conditions

“Today’s tapes are resistant to UV and heat and rain. How do we know? We stick them outside for years and watch them and we also take apart older buildings that have used them to see how well they did,” Lstiburek writes. “Nothing beats real world exposure.”

“On some substrates — especially the foil-faced polyiso, the housewrap, and the polyethylene — the best tapes were so tenacious that the substrates were damaged by my attempts to remove the tape,” writes Holladay.

That says a lot about the power of tape to establish a permanent, weather-tight bond. However, is it safe to assume that if water penetrates the structure, it’s the construction tape’s fault?

Not necessarily.

You’ve heard the expression, “location, location, location.” Well, when it comes to adhesive tape sticking in the rain and other tricky field conditions, that might as well be: application, application, application.

Best Practices for Adhesive Tape Application

Building America℠ asked contractors and homebuilders to identify three significant strategies for successfully using taped insulating sheathing as the drainage plane:

- Limit or eliminate horizontal joints wherever possible.

- Where a horizontal joint exists, use superior materials.

- Require frequent installation inspection and regular trade training to ensure proper installation.

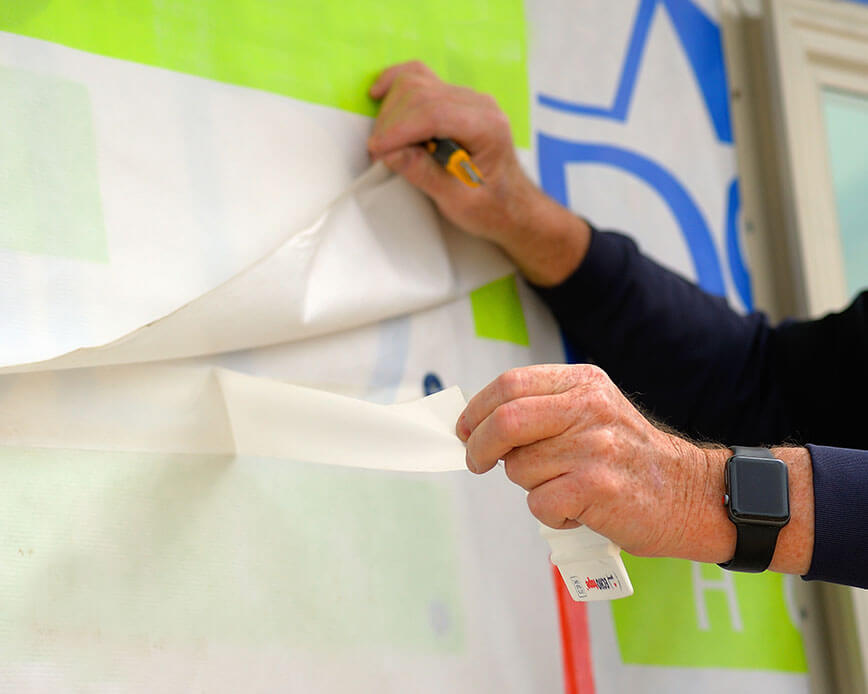

Installers also found that tape should be offset, favoring more tape on the upper sheet of the substrate. A decent rule is that 2/3 of the tape should be on the top sheet, and the remainder lapped over the bottom sheet.

Commissioned by Building America, Lstiburek and Grin created a Measure Guideline and Report (2014) on taped insulating sheathing drainage planes. Here are six key takeaways:

- Z-flashings can be used on all horizontal joints and should be used on any high-risk horizontal joint.

- Drainage planes and tapes must be smooth, clean, dust free, and ideally warm.

- A termination strip of thin tape should always be used for thick tapes.

- Backup wood blocking should be installed behind horizontal joint locations.

- Vertical joints should land on framing members and be taped with a minimum 3” wide acrylic tape and gravity lapped with the horizontal joint.

- In terms of flashing tapes, almost all groups interviewed prefer butyl based tapes over asphaltic based tapes.

In the end, what tape did they recommend for such a job? An acrylic adhesive based, superior thin tape, available in wide widths up to 4”, and has good temperature and UV resistance. Builders also responded that, through their experience, superior thin tape should be able to adhere to almost any substrate with high reliability in a range of climatic situations.

When it comes to superior flashing tape characteristics, the report indicated that a butyl adhesive based flashing tape, not more than 20 mil thick to ensure overlaps do not build-up too much, available in 6”, 9”, and 12” widths, and should have a facer that is very expansion/contraction compatible with its adhesive substrate.

Builders noted that the best flashing has a facer that is no wider than the adhesive as to not trap water and has good temperature and UV resistance. Again, superior flashing tape will be able to adhere to almost any substrate with high reliability in a range of climatic situations.

With any tape for it to function well, it must be firmly pressed into place. This is particularly important with acrylic tape systems. They should be installed with a roller or squeegee to maximize contact.

“Many of the problems related to the seam seal tape start with the wrap installation, particularly the fastener placement. Oftentimes cap fasteners installed at the tape edge prevent a complete seal. Wrinkles in the wrap can leave voids at the tape contact surface,” writes Jeff Hoch. “All of these conditions can allow water to migrate behind the tape, follow the horizontal seam to the nearest vertical seam, and ultimately into the structure. Since most areas of housewrap are over wood-based sheathing, leaks at the seams may go undiscovered for years.”

Advancements in Adhesives and Tape Specialization

“Just because a tape does well on one substrate doesn’t mean it will work well on another,” cautions Holladay.

“At the end of the day, taped sheathings work as well as building wraps and housewraps and vice versa,” writes Lstiburek. “But there are limitations to both. With building wraps and housewraps the biggest single problem is making sure gravity laps are actually used. Amazing as it seems reverse lapping is still the most common residential construction defect I see. With construction tapes the biggest single problem is folks thinking they can stick them to muddy, dirty, cold, wet and frozen surfaces. You would think this is obvious… [yet] folks keep trying to do it.”

Of course, this is just one expert opinion. What it all boils down to is knowing these three things: your job, your materials, and your field conditions. Only then can you match the right adhesive with your project.