Double-sided tape is any tape that is coated with adhesive on both sides. Designed to stick two surfaces together without being seen, these versatile tapes deliver neater-looking projects and better craftsmanship. And unlike screws or rivets – which join materials at a single point – high-strength double-sided tape permanently adheres one substrate to another while spreading the stress load.

Sounds great, right!? Yet, much like everything else on the job site, choosing the right double-sided tape for the specific application is not as easy as it sounds. Whether you’re bonding glass, wood, steel, concrete, foam, and/or plastic together, it’s important to understand the materials you are bonding. Concrete with a textured surface is going to require more adhesive strength than, say, carpet padding.

Best Uses for Double-Sided Tape in Construction

Outside of materials, it’s also important to understand the field conditions. A product that you used in spring or summer might not work in sub-zero winter. Ice, rain, humidity, heat, UV, and dirt are all factors to consider when choosing the right tape or, more importantly, preventing tape failure. For more on this, check out our infographic, The Secret to Choosing the Right Tape.

That said, we are thrilled to see more and more tape being used in construction applications, especially since adhesive technology has come a long way. As more and more builders start to focus on seaming the building envelope and getting improved HERS scores, tape is fast becoming a way to get the job done well. Here are just some of the construction applications where double-sided tape plays a major role and we expect more and more in the future.

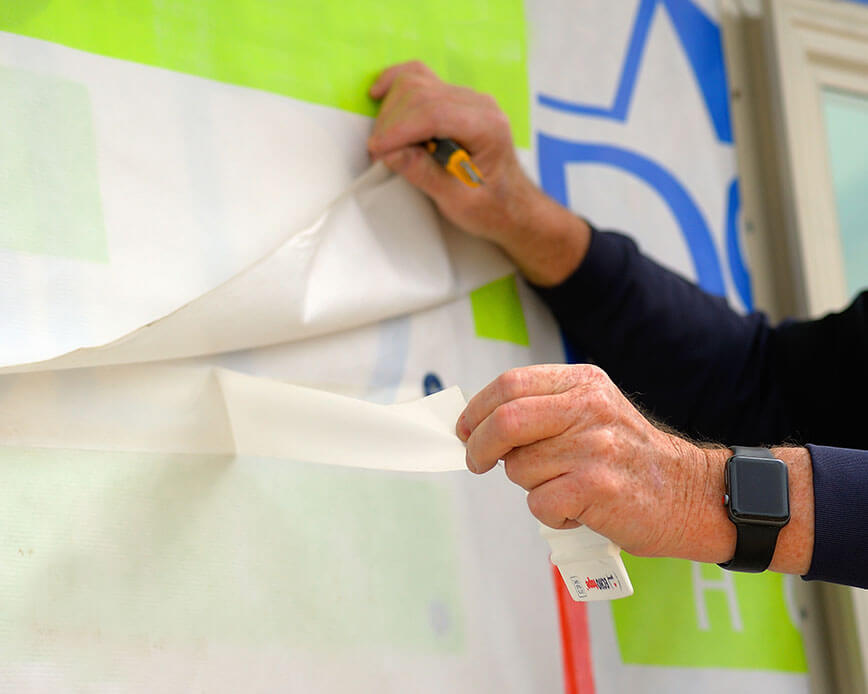

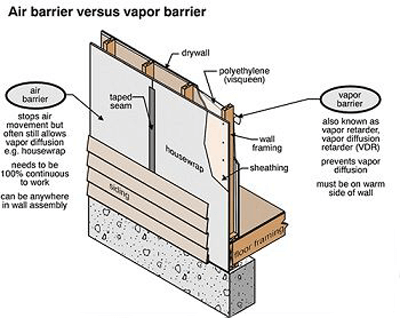

Overlap housewrap seams. Here’s the deal: single-sided tape used to seal housewrap may allow water to migrate behind the tape, and ultimately into the structure. Using a roller to bond the tape may help, but the better solution is to use double-sided tape as a housewrap tape so you can overlap seams and ensure no water gets through.

Overlap vapor barrier seams and attach them to cement walls in crawlspaces. More and more builders are putting vapor barriers down in crawlspaces to seam the building envelope as even in the basement there is air leakage. You can also use a high-performance double-sided vapor barrier tape to attach the barrier to the walls instead of using screws.

Overlap any flooring underlayment including sound attenuation barriers. With more buildings becoming airtight, sound is becoming a big issue. Use double-sided tape for any flooring underlayment including sound attenuation materials.

Permanently attach insulation to walls. Use double-sided insulation tape to attach insulation to the building and ensure it sticks.

Temporarily mount something prior to permanently fastening. Temporary double-sided tape is the perfect solution to hold something in place while you permanently mount it. Examples include light switch junction boxes; electrical panels; electronic thermostats; baseboards; and crown moldings.

Floor protection. Often you need to cover floors or walkways with carpets or floorboards to protect the surface while construction is underway. Our double-coated carpet tape features an aggressive adhesive system that’s perfect for carpet hold-down but will leave no residue once removed.

Easy installation of building materials. More and more manufacturers are making their products with double-sided tape for easy installation. As labor shortage becomes a big issue, finding ways to save installation time is becoming critical.

For more information on double-coated adhesive tapes, please visit The Complete Technical Guide to Double-Sided Tape. And if you still have questions, please contact us! We love solving unique tape challenges.