Everyone instinctively knows that when you go outside on a cold day, you must zip your coat to stay warm. It doesn’t matter how thick the coat is, if it’s left open, your body heat will leak out.

The same is true with building insulation — no matter its R-value (thermal performance), if insulation isn’t continuous throughout the building envelope like a zipped coat, heat will escape – wasting energy and money. Hence the term continuous insulation.

What is Continuous Insulation?

Continuous insulation, also known as outsulation, is defined in American Society of Heating, Refrigerating and Air-conditioning Engineers 90.1 (ASHRAE 90.1), as:

“Insulation that is continuous across all structural members without thermal bridges other than fasteners and service openings. It is installed on the interior, exterior, or is integral to any opaque surface of the building envelope.”

To help ensure well-insulated buildings, since 2012, the International Energy Conservation Code (IECC) has required continuous insulation (CI) in the building envelope. The 2012 IECC prescribes how much insulation is required for each of the 8 U.S. climate zones, for various types of above-grade walls, below-grade walls, roofs, and floors.

Notably, this requirement eliminates the use of fiberglass batts installed between wall studs as the sole means of insulation, which had been common practice in construction for decades. Such insulation can still be used, but continuous insulation installed over the studs, such as rigid foam, must also be applied.

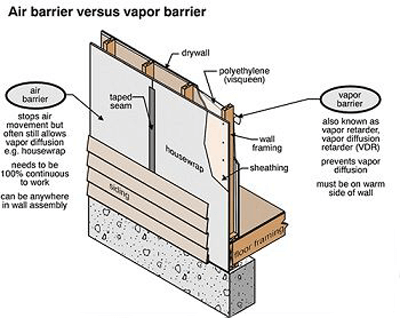

In addition to enhancing a building’s energy efficiency, CI helps reduce moisture damage in the building envelope by lowering condensation within the envelope assembly resulting from vapor diffusion.

Why Continuous Insulation Really Matters

As a highly industrialized nation, the United States consumes energy in many areas including manufacturing, transportation, and construction.

According to the U.S. Green Building Council, “buildings account for approximately 40 percent of the total energy used today… and 38 percent of total carbon dioxide emissions in the United States,” which amounts to higher energy use than in the entire transportation industry.

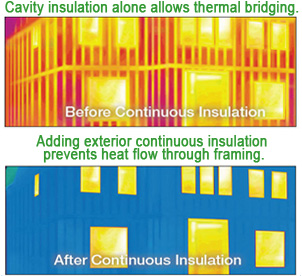

Obviously, the U.S. Department of Energy (DOE) realized that if they were truly going to make a difference in the environment, they had to tackle the biggest culprit — buildings. Specifically, thermal bridging.

If you’ve been around the construction and insulation industry you probably know the term. Thermal bridging, also known as cold bridges or heat bridges, are penetrations in a building’s insulation layer that allow heat (a.k.a. energy) to escape and cold to intrude during winter. Vice versa in the summer. In an airtight and insulated home, thermal bridges can account for heat loss of up to 30 percent.

As more stringent legislation and energy awareness lead to increased insulation levels in walls, roofs, and floors, heat losses due to thermal bridging become increasingly important. We discuss the topic of thermal bridges in depth here.

[echo_cta]

Continuous Insulation In the Field

Perhaps the best way to understand how CI impacts high-performance home builders is via the following example by GreenBuildingAdvisor.com:

It’s been calculated that a 2×4 wall with R-13 insulation in the cavity actually has a whole-wall R-value of only R-11, and a 2×6 wall with R-20 insulation is actually performing at R-15.67. So… What happens when we add rigid insulation to the exterior?

Let’s take a 2×4 wood framed wall with R-13 fluffy stuff in the cavity and R-5 on the exterior to minimize thermal bridging and air infiltration. The combined R-value is R-17.26, while a 2×6 wall without external insulation measures R-15.67. So the 2×4 wall with continuous insulation actually performs better than the 2×6 wall without continuous insulation (CI).

This can save you money in construction as well as giving you more space inside. The exterior wall insulation can make it perform up to 50 percent better than the same wall without the rigid foam insulation.

Furthermore, studies done by the Oak Ridge National Laboratory (ORNL) found that thermal bridging through framing components reduces insulation performance by as much as 15-20 percent in wood frame construction and by 40-60 percent in metal framed buildings.

The installation of proper amounts of continuous insulation maximizes the full R-value of the insulation products. Continuous insulation on outbound exterior walls, alone are in tandem with interior insulation efforts, is the most efficient way of achieving improved R-values.

Rigid foam plastic sheathing materials are commonly used for continuous insulation because of their relatively high R-value per inch and low cost to meet or exceed energy code requirements. [We discuss the pros and cons of Rigid Foam Sheathing here and here.]

Other common continuous insulation solutions include:

- Spray foam

- Fiberglass boards

- Fiberboard

- Rock wool

How Tape Is Being Used with Continuous Insulation

Improving the energy efficiency of all buildings will reduce the consumption of non-renewable fossil fuels, lessen dependence on foreign sources of that energy, and curtail greenhouse gas emissions. That’s all good, but what does this have to do with tape?

Related: compare our top insulation tapes

It is obvious to us that as customers demand more energy-efficient homes and building codes become more strict, adhesive technologies will play a major role in the application and effectiveness of ci.

Here are just a few ways builders and contractors can use tape more effectively in sealing the building envelope:

- Tape all insulation seams to create an air/water-resistive barrier

- Seal all penetrations with tape to create airtight seals

- Create a continuous air/water barrier at the roof and foundation wall interface by taping all transition seams

In the long run, continuous insulation not only dramatically reduces building management costs, but the improvements in efficiency, help the building industry move closer to carbon neutrality and a more sustainable environment.